Air-X - Oil Aeration Measurement

Air-X - Oil Aeration Measurement

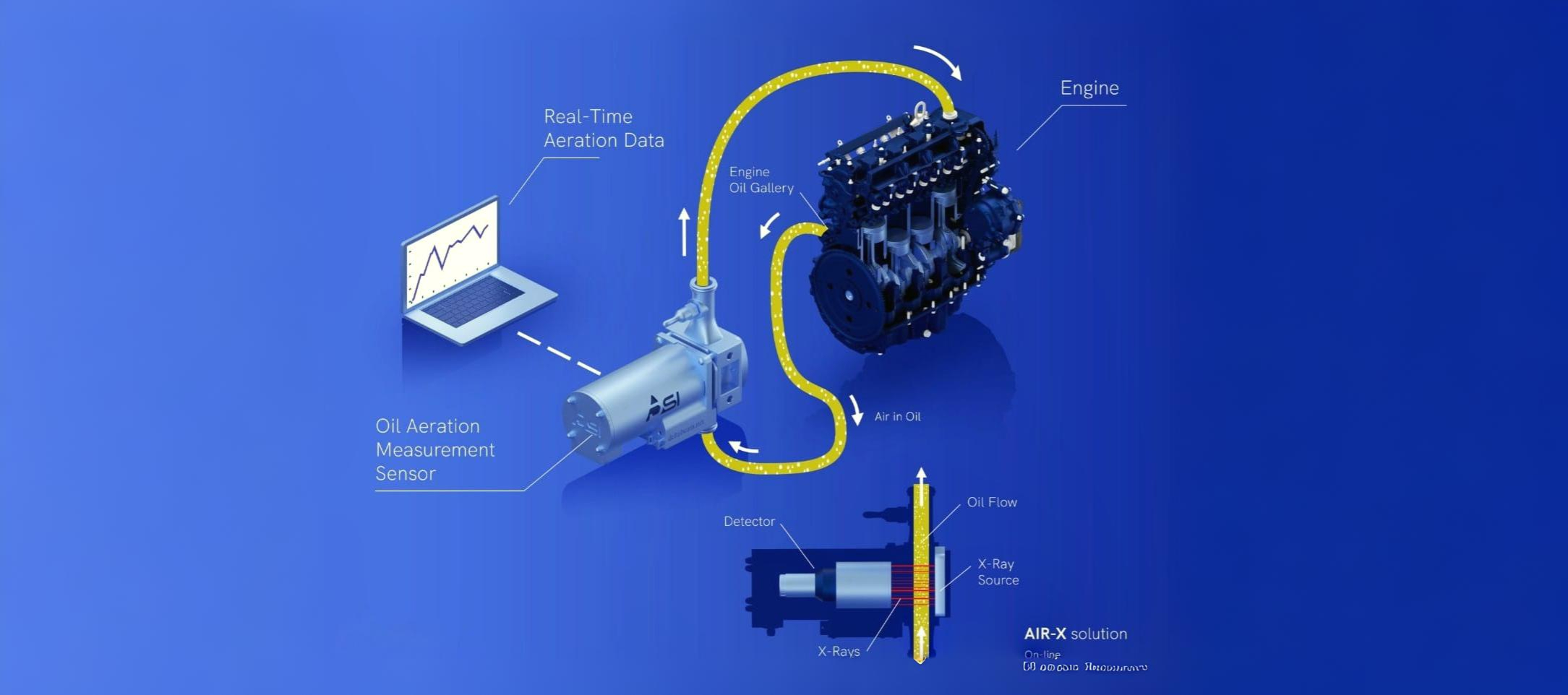

Air-X is an instrument designed for on-line monitoring of oil aeration in a running mechanical system. The operating principle is based on an accurate density measurement using X-ray transmission. An oil sample coming from the mechanical system is circulated continuously into a compact measuring chamber where the density measurement is performed.Applicable on all fluids, our equipment, originally applied on engines, can be used in a lot of applications.

Online Oil Aeration Monitoring

Air-X is an advanced instrument designed for continuous, real-time monitoring of oil aeration in running mechanical systems to ensure optimal performance and reliability.

X-Ray Density Measurement Technology

The operating principle is based on highly accurate density measurement using X-ray transmission, allowing precise detection of entrained air within lubricating fluids.

Continuous Sampling & Measurement

An oil sample from the mechanical system is continuously circulated through a compact measuring chamber, ensuring uninterrupted monitoring during real operating conditions.

Multi-Fluid & Multi-Application Use

Applicable to all types of fluids, Air-X is suitable not only for engines but also for a wide range of industrial and mechanical applications.

Working & Applications

Air-X continuously measures fluid density using X-ray transmission to accurately detect oil aeration. Real-time monitoring helps prevent lubrication failures, improves system efficiency, and extends component life.